I. Background

Most of Mozambique’s smallholder farmers practice subsistence agriculture and farming, mainly for household consumption, and have limited ability to produce surplus as most of them store their grain in traditional or renovated traditional silos, which result in high losses (around 30%) and put farmers’ economic and food security status at risk. To address this issue, between 2017 and 2020 with Cartier Philanthropy’s support WFP piloted the introduction of hermetic bags in the Tete province through the Zero Food Loss for Farming Families Supplying Schools project. Phase 1 of the project has demonstrated that hermetic storage technology helps farmers reduce postharvest losses from 50 % to 9 % of the produce and create up to a 35.31 % increase in their income. Post-harvest loss reduction, and the use of hermetic bags particularly, can thus trigger increased production and productivity which generates improved quality food surpluses suitable for selling at better prices, particularly during the lean season. Farmers recover the cost of the hermetic bags in one season and can use the bags for another two years after that. Because of their low cost, their scalability and reliability, hermetic bags are also a low-risk investment.

Following upon results of the phase I of the project and in preparation to implement the phase II of the project, namely Scaling-Up the Zero Food Loss Initiative in Mozambique, WFP will implement the phase II to tackle postharvest losses through an innovative strategy that combines value chain approach, focus on scaling of proven technologies, partnering and collaborating with Government, NGOs, UN agencies and private sector, and capacity development of farmers. WFP Mozambique aims to support farming families in reducing postharvest losses, through improved post-harvest management through technology promotion, capacity development of local market actors and policy advocacy and dentification and implementation of market-based response strategies to postharvest losses reduction, including engagement with the private sector for long term sustainability.

Through the Zero Food Loss for Farming Families Supplying Schools project, WFP also supported the smallholder farmers grouped in farmers organizations (FO) to reduce the post-harvest losses of fruits and vegetables linking them with the schools that acted as majority buyers of FOs fresh products. All the FOs that supplied the schools with fresh vegetables are on the south districts of Tete where are registered high fresh products production by smallholder farmers.

II. Objectives

General mission objective: Promote the use of many delicious, nutritious and potentially profitable food products that can be prepared from orange-fleshed sweet potatoes. The use of sweet potato as animal feed is also discussed.

The expected results are as follows:

By the end of this training, you should be able to:

1) Identify the sweet potato processing practices that best preserve beta‐carotene.

2) Describe the processes of boiling, steaming, roasting, and drying sweet potato root.

3) Discuss the pros and cons of peeling sweet potato.

4) Tell how to improve beta‐carotene retention within each processing method.

5) List the three primary orange‐fleshed sweet potato (OFSP) products.

6) Explain how to add nutritional value to a variety of foods using processed OFSP or other tuberculosis.

III. Training Modules

The training will be organized in one day with 1 module, which contains a 90-minutes lecture and 20 minutes Q&A.

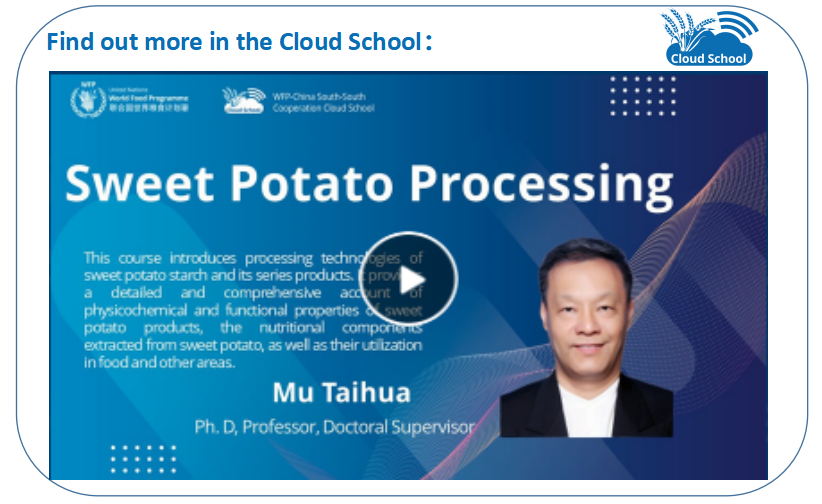

Training topic: Key Technologies of Sweet Potato Processing and Comprehensive Utilization of its by-Products

Trainer: Dr. Prof. Mu Taihua, Professor, Chinese Academy of Agricultural Sciences(CAAS)

IV. Training Arrangement

● Participants

16 people from WFP Mozambique and Mozambique government

● Language

Chinese with translation into Portuguese during the training

● Follow-up

The workshop presentation slides and recordings will feed the WFP-China South-South Cooperation Knowledge Sharing Platform and Cloud School

Agenda